Home / Making it Move: Steam, Gravity & Electricity

Making it Move: Steam, Gravity & Electricity

Steam, gravity, and electricity have all been used as power sources for Louisville Water’s water works operations.

The Cornish Pumps

The Cornish Pumps

Steam was a common source of power during the nineteenth century. It powered factories, boats, trains, and, of course, pumps. Coal was often the fuel to create steam.

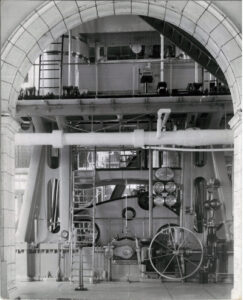

In 1860, two Cornish pumps powered the original Water Works. Steam pushed down the cylinder raising the plunger to pull in water from the Ohio River. When the steam was released, the 58,000 pound plunger fell forcing 527 gallons of water up to the original reservoir on the bluffs overlooking the pumping station.

How much is 58,000 pounds? An average African elephant weighs 12,000 to 15,000 pounds. You’d need four elephants to equal 58,000 pounds!

These pumps were highly reliable and simple to maintain. They were Louisville Water’s main pumps for over 30 years. During the last five years of operation they worked nearly 24 hours a day, 365 days a year. The pumps were dismantled in 1911; its many tons of cast iron were sold for scrap.

Gravity Supplies Water to the City

Louisville Water has always used gravity; the greenest power source. In the beginning, gravity was not only used to drop the plungers of the huge Cornish Pumps it also provided the pressure in the pipes form the reservoir into the city. That is why it was important to locate the reservoir on high ground above the city.

Louisville Water used gravity as the sole source of pressure in its distribution pipes for nearly 50 years until the Crescent Hill Pumping Station went online in 1907.

More Water!

More Water!

By 1880, the demand for water was growing fast; planning began for a new pump station with a larger and more efficient steam pumping engine.

In 1893, Pump Station No. 2 with its Hermany-Leavitt pumping engine went into service. Capable of pumping 16 million gallons a day, Louisville Water’s pumping capacity more than doubled. The Hermany- Leavitt was lauded as the most efficient steam pump of its day.

The Hermany- Leavitt, a double expansion pump, had two cylinders and a 36-foot fly wheel to make it a model of efficiency.

“The Quiet Giant”

In 1919, an Allis Chalmers triple expansion pump engine, “The Quiet Giant” (capable of pumping 30 million gallons a day) went into operation. It used three cylinders and two flywheels to help keep the engine turning. The pump is still in Station No. 3 making it one of the few remaining triple expansion steam engines in the United States.

Watch this video to see the steam engine in action as it was filmed in 1938 and again in 1964. It took 25 men to operate the steam pump engine. In three shifts, over a 24 hour period, men worked to monitor the operation of the pump and keep the boilers burning.

Electricity Comes of Age

It wasn’t until Louisville Gas & Electric Company built the hydroelectric plant, in 1926, at the Falls of the Ohio that electricity became a plentiful and relatively inexpensive power source for the city.

It wasn’t until Louisville Gas & Electric Company built the hydroelectric plant, in 1926, at the Falls of the Ohio that electricity became a plentiful and relatively inexpensive power source for the city.

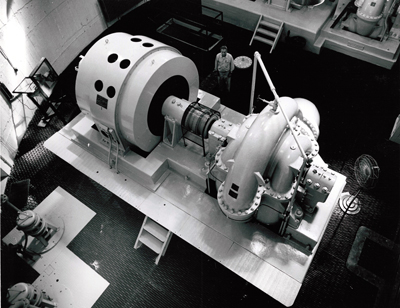

In 1928, Louisville Water signed a contract with LG&E for a new electric powered 60 MGD pump. This was the beginning of the end to the reign of steam. Once the electric pump became operational the boilers were allowed to go cold; the steam engines at the River Pumping Station became backup pumps in case of emergency.

While the old and new pumps resided side by side for a number of years, it was the end of the steam era for Louisville Water. One by one the old steam pumps were dismantled and sold for scrap.